Delivery Section

1. Automatic paper collecting is realized.

2. To guarantee the continuous collection, when the paper pile reaches a certain height, the paper plate shall be inserted into the paper pile, and the paper collection can be finished.

3. Side paper and back paper making device ensures that the paper pick-up brush and the paper-collecting flop device avoid paper shake. The position of each device can be adjusted to suit different layouts.

Electric Control Section

1. The electrical system adopts advanced control devices such as PLC programmable controller and man-machine interface.

2. The man-machine interface monitors the operating status of the machine, the input and output points of the programmable controller, and various faults. In addition, Chinese and English are also provided for troubleshooting and operation.

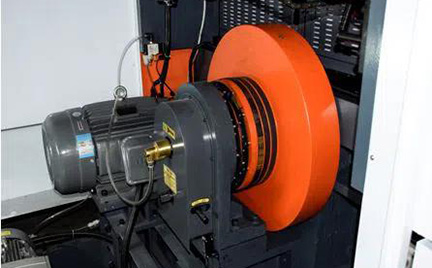

3. The main motor is controlled by a frequency converter, with stepless speed regulation, low noise and energy saving.

4. The main drive adopts pneumatic clutch or electromagnetic clutch, which is safe and reliable in operation.

5. Many photoelectric switches are installed on paper feeding, die cutting and paper delivery to ensure the safety and smoothness of the whole process.

6. Use multimedia technology to realize data input, setting, etc. more convenient.

7. Multi-layer indicator lights show the different working status of the machine, and are equipped with alarm devices to remind others to pay attention to safety.

8. According to the principle of ergonomics, there are many operation button boards, such as paper feeding part, conveying surface, operation surface and paper output part, so as to realize the control of different parts of the machine.

9. Use three-phase four-wire AC 380V 50HZ power supply. The machine has a special protective grounding wire PE.

10. Each part adopts safety switches to ensure safe operation and safety facilities comply with CE standards.

Hot Tags: paper cutting machine, China, manufacturers, suppliers, factory, price, carton, box, automatic, corrugated, high speed, Xinlian, made in China, paper grid molding machine, wrapping machine, prefolding folder gluer, Paper Book glue machine, Two Cartons Glue Machine, corrugated stripper.