Specifications

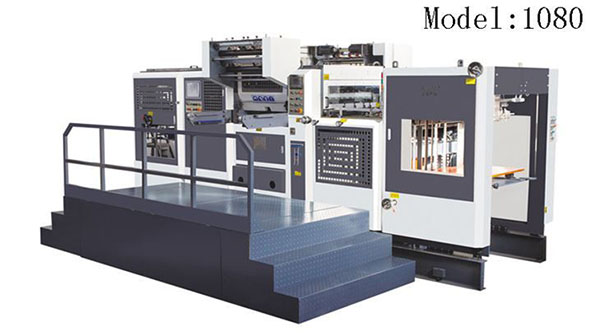

| Model | XLTYM-1080 |

| Max. Paper Size(mm) | 1080×780mm |

| Min. Paper Size(mm) | 400×370mm |

| Max. Die-cutting Size: (mm) | 1070×770mm |

| Max. Foil Stamping Size: (mm) | 1020*710mm |

| Max. Working Speed | 7000s/h |

| Max. Stamping Speed | 5500s/h |

| Max Pressure | 300T |

| Stamping Setting Temperature | 0-199℃ |

| Max Foil Diameter | Φ100mm/1"Φ195mm/3" |

| Max. Longitudinal foil length | 710mm |

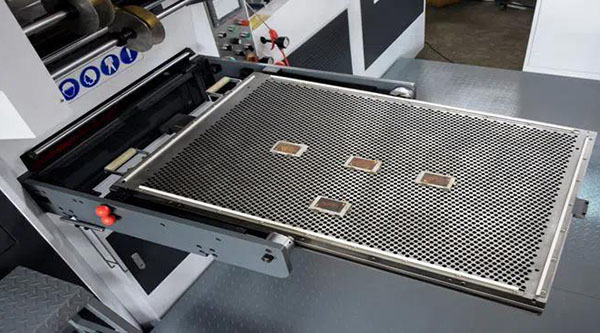

| Max. Lateral foil length | 1020mm |

| Heating quality | 12 |

| Longitudinal foil shaft | 3QTY |

| Lateral foil shaft | 2QTY |

| Min. Foil length | 0.01mm |

| Sheet Thickness | Corrugated≤4mm |

| 0.1mm≤Paperboard≤1.5mm | |

| Heating plate power | 24KW |

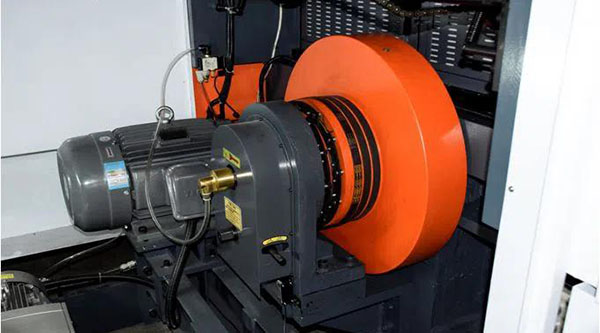

| Main motor power | 15KW |

| Total power | 56KW |

| Total weight | 18T |

| Overall Dimensions(mm) | 6000*4000*2300mm (not include pre-loading part) |

Main feather

The Automatic Foil Stamping & Die-cutting Machine is equipped with the horizontal and vertical foil stamping device, the structure is reasonable, the operation is convenient, is widely used for the die-cutting , creasing, foil stamping, cold and hot embossing of cigarette box, drug box and label in the packaging and decoration industries. The machine adopt the high technology to realize the fully automatic feeding, die-cutting, stamping, delivery, up-press, down-press, leap step, counting, heating, pre-heating, obstacle indicating, checking and measuring. With the feather of easy operation, reliability, high speed, pressure and precision.

It is certified by ISO9001 quality system and meets CE safety standard.

Features

I. Paper Feeder Section

1. This machine adopts heavy-duty high-speed feeder adapting to the high-speed and steady delivery of all kinds of paper.

2. The whole machine is raised and equipped with pre-coding paper device.

3. Using fish scale paper delivery method. The use of side blowing to make paper more smooth.

4. Feeder head and paper pile adjustment has been optimized to make the operation more flexible, convenient and improve the accuracy of paper pile positioning.

5. Taiwan's high-quality gear motor, low noise, high torque, to ensure a smooth pile of paper movements.

II. Foil Stamping

1. The main parts of the main machine (including the base, the stage, moving table and wallboard) are made of high-quality resin sand ductile iron casting, greatly improving the mechanical strength and ensuring the service life of the machine; Open teeth and other institutions adopt the Swiss BOBST paper structure, so that the smooth operation of the machine reliability, accuracy and stability.

2. Italy imported pneumatic clutch, which not only has the advantages of small size, good heat dissipation, short response time, and easy maintenance and replacement, suitable for high frequency use.

3. Die-cutting department designed a reasonable structure of the elbow bar pressurized mechanism, at the same time through sophisticated processing and assembly process, the accuracy of the machine reached a higher level. Die cutting pressure of 300 tons of the largest machine, to meet the requirements of bronzing process.

4. Automatic pressure adjustment mechanism controlled by frequency converter, while improving efficiency, make pressure adjustment more convenient, smooth, accurate and fast.

5. Automatic control of the cylinder die cutting knife version of the lock, so that the operation becomes simple and reliable.

6. Flexible and reliable piracy device and the middle of the frame locator, so that the plate installed quickly and accurately.

7. Optimized design of the chain of institutions using high-quality hard aluminum tooth row body and the import chain, greatly reducing the running inertia, more adapt to high-speed production.

8. The use of 230 ° precision intermittent mechanism, together with the machine can ensure smooth operation of the machine at the same time on the platform, tooth row and body effective protection.

9. Steel selection of high hardness, high elasticity material, good flatness, durability; its positioning device effectively ensure accurate positioning.

10. Host Department of rain lubrication, equipped with oil cooling device, suitable for users in different regions. Transmission part of the machine is equipped with automatic lubrication device, greatly extending the life of the machine.

11. Local 12 heating zones, heating wire arrangement interval is small, accurate temperature control, uniform. Each zone temperature can be individually controlled adjustment!

12. High strength honeycomb panel is not easy to deformation, high flatness. Heat-resistant rail to ensure that the foil is not deformed, accurate and stable delivery.

13. Foil rack can be pulled out to the outside of the machine, replacing aluminum foil is simple, save time.

14. Aluminum foil stripping blowing control valve can be adjusted blowing air volume, to avoid large-scale hot stamping foil off the paper.

III.Delivery Section

1. using high-quality Taiwan motor gearbox, low noise, large torque, to ensure that the paper pile heap stable. And with the car does not close the fence to greatly improve the production efficiency.

2. Optimized design of the brush brake device can achieve non-stop adjustment, so that paper collection more stable and tidy.

3. Increased paper blowing and rear air blowing devices adapt to different paper collections.

4. Pneumatic sampling structure reflects the more humane design, make the operation more simple and quick.

IV. Electric Control Section

1. The electrical part of the machine is designed according to CE standard. All kinds of protection are tested by switch.

2. Electrical box with air conditioning and refrigeration, greatly extending the life of electrical components.

3. The machine adopts high-tech, to achieve from the paper, die-cutting to the delivery of paper automation.

4. Adopt encoder, electronic cam composed with programmable controller is more reliable and easy to adjust; inverter is used to control the main motor, stepless speed regulation and stable operation.

5. In accordance with ergonomic principles, with multiple operation button board, such as the paper to the site, the transmission surface, the operating surface and the delivery site, to achieve different parts of the machine control.

6. The machine also has the automatic fault detection (including double, plot paper, paper and other testing), non-stop sampling and other functions, but die cutting pressure, high register accuracy.

7. This machine adopts horizontal and vertical double-direction hot stamping design. Longitudinal and horizontal hot stamping can be carried out at the same time, greatly reducing the loss rate of hot stamping foil. Some products can finish the original traditional hot stamping work twice.

Hot Tags: foil stamping. die cutting machine, carton box. factory. Aluminum foil. deep embossing. manufacturers, suppliers, carton, box, automatic, corrugated, high precision. gripper. chain. die cutter, folder gluer, die cutting &creasing machine, PE Pet PVC Plastic Film Adhesive machine, Manual Punching Eyeleting Machine, case making machine, folding machine in Paper Processing