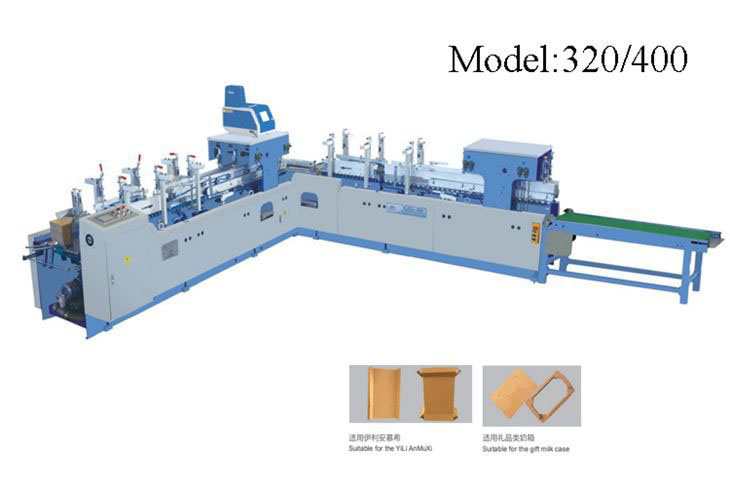

Factory Supply Automatic Double Head Binding Machine - Cardboard Gasket Folding Machine – Lianji Detail:

Tips Of the Machine

1. High precision: The precision can be up to at ±0.075mm by fine adjustment. The machine can do the press copybook and other kinds of high precision products.

2. The platform is flat. The flatness precision can be controlled at 0.05mm. Basically, there is no need to use a pad when making a sticker. It takes only 12 minutes to change the sticker.

3. High speed: It can run 7500sheets per hour, and noise is under 75 decibels.

4. Taiwan brand feeder can run thin paper, laminated paper smoothly and stably. It reduces the downtime due to double pieces of paper or the paper not being in place.

5. The intermittent device is made in Taiwan with good stability and long service life.

6. The machine adopts Japanese electric appliance, SMC rotary joint, Italian pneumatic clutch and Siemens main motor.

7. The machine can equip with heating system, the PVC material feeding can select single type or overlap type to avoid scraping, one button order for this change makes the operation easy and convenient.

8. The machine equip with the blowing device in delivery unit, and the thin paper will be neatly collected.

Note: The last two tips is for special requirement of PVC Cutting.

Main Specification

| Model | XLZGJ-320 |

| Max. Paper Size(mm) | 280*320 |

| Mn. Paper Size(mm) | 150*150 |

| Total Power(including gluing system) | 13kw |

| Power | 8.5kw |

| Speed | 6000-10000s/h |

| Overall Dimensions(mm) | 3750*900*1300+3480*1150*1900 |

| Total Weight | 4T |

Main Feathers

1. The machine is designed reasonably, simple structure, and operation convenient.

2. The max. Speed is 80-120 m/min.

3. The electrical adopt the touch screen, frequency converter drive, PLC, photoelectric detection, the automatic control is more reliable, precision is more accurate, adjustment is more convenient.

4. Adopting the double tooth rod adjustment to change the products, simple and convenient.

5. The paper conveying adopt the servo motor, equipped with the down suction, import rotary encoder, paper delivery accurate.

6. Import hot adhesive system, gluing accurate and firmly. The forming is 180° and 90°two parts, suitable for the four sides gluing, forming products.

Hot Tags: cardboard gasket folding machine, China, manufacturers, suppliers, factory, price, carton, box, automatic, corrugated, high speed, Xinlian, made in China, hardcover making machine, Carton Flute, manual feeding stripping machine, double lines pasting machine, four and six corners gluer, High Speed Pre Coating Film Laminator.

Product detail pictures:

Related Product Guide:

Using a complete scientific high quality management program, superior high quality and superior faith, we acquire great reputation and occupied this industry for Factory Supply Automatic Double Head Binding Machine - Cardboard Gasket Folding Machine – Lianji, The product will supply to all over the world, such as: Doha, Tanzania, Argentina, Further, we are supported by highly experienced and knowledgeable professionals, who have immense expertise in their respective domain. These professionals work in close coordination with each other to offer our clients an effective range of products.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.