Description

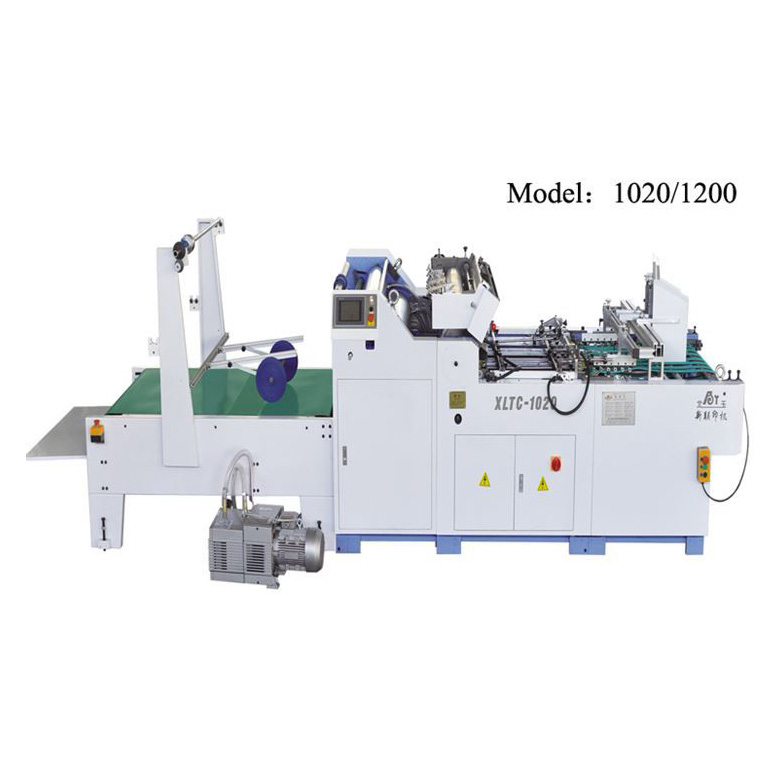

Tissue box window patching machine 1020/1200

The machine could equipped with napkin box structure.

| Model | XLTC-1020 | XLTC-1200 |

| Max. Paper Size | 1080×630mm | 1200×720mm |

| Min. Paper Size | 140×140mm | 140×140mm |

| Max. Film Size | 410×300mm | 410×300mm |

| Min. Film Size | 80×60mm | 80×60mm |

| Film Thickness | 0.05-0.20mm | 0.05-0.20mm |

| Max. working speed | 8000s/h | 6000s/h |

| Carboard | 200-500g/㎡ | 200-500g/㎡ |

| Corrugated Paper | ≤7mm | ≤7mm |

| Total Power | 9Kw | 10Kw |

| Total Weight | 3000kg | 3500kg |

| Overall Dimensions | 5000×1960×1750mm | 6200×2000×1750mm |

| (When the roller pull out the dimensions) | 5000×3160×1750mm | 6200×3260×1750mm |

Features of the machine

1. Window patching machines are widely used in the packaging of paper products for windows without windows, such as mobile phone boxes, wine boxes, napkin boxes, clothes boxes, cake boxes, cards, etc. It can also be used to paste paper onto part of the surface.

2. The machine adopts PLC, man-machine interface, photoelectric tracking and central control to realize automatic paper feeding, conveying, window glue or part of flat glue, part of sticker, cutting film gap, film, paper automatic function before folding box (especially preparation in advance) Good film cutting and creasing, wrinkles can be avoided when packing the box).

3. The paper feeding part adopts servo system, realizing precise inch-move, fast-speed paper feeding ,stable working state and excellent precision in operation.

4. The integrated suction belt feeder has high precision. The alignment of the window and film is accurate, almost error-free, adjustable, the whole machine is convenient and easy to operate.

5. Using a specially designed structure glue,glue evenly, glue size adjustable save glue, cleaning can be pulled out for easy operation, convenient maintenance.

6. The human-machine interface adopts the Delta series, which can be translated into multiple The transmission belt and chain adopt well-known domestic and foreign brands. Stable and durable, providing high-quality guarantee in quality.

7. All bearings are made of Japanese NSK and well-known domestic brands.

The materials in contact with paper are all non-toxic products, which meet the hygiene and safety standards.

8. The rubber roller motor is a joint venture product, and the inverter is controlled separately.

FAQ

1. Does the packing strong?

Yes, of course! All of our export packing is with strong pallets, all are confirmed to export packing standard.

2. How about after-sales service process?

When your machine has problem, contact your sales and we will solve your problem as soon as possible.

3. Are you manufacturer?

Yes, Our parent company has been engaged in manufacturing for more than 20 years. We are manufacturer with 10-year experience and profession.

Hot Tags: Tissue box Window Patching Machine, China, manufacturers, suppliers, factory, price, carton, box, automatic, corrugated, high speed, Xinlian, made in China, Automatic Water-Based Film Laminator Machine, paper bag making machine, PE Pet PVC Plastic Film Adhesive machine, Cheaper folder gluer, manual die cutter, High Speed Automatic Die Cut Machine.