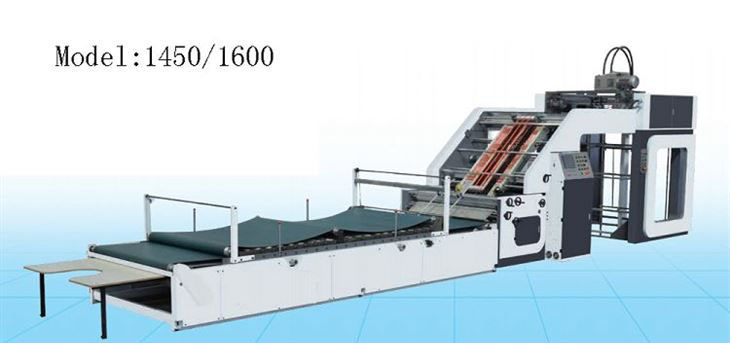

High definition Big Laminator - High Speed Servo Automatic Flute Laminator – Lianji Detail:

Description

Servo high speed laminating machine 1450/1650

Specifications

| Model | 1450 | 1650 |

| Max. Paper Size | 1450*1300mm | 1650*1450mm |

| Min. Paper Size | 400*400mm | 400*400mm |

| Face paper thickness | 150-600g | 150-600g |

| Bottom paper Thickness | ≤10mm | ≤10mm |

| Max. working speed | 150m/min | 150m/min |

| Laminated precision | ±1mm | ±1mm |

| Total Power | 20Kw | 22Kw |

| Total Weight | 7500kg | 8000kg |

| Overall Dimensions | 13500*2300*2500mm | 14000*2500*2500mm |

Function feathers

High Precision: At normal speed the precision can be controlled at ±1 mm with the yield 98%.

High Speed: It can run 12000 sheets per hours for sheet length 450mm.

General Introduction

This series High Speed Automatic Flute Laminator is suitable for the lamination of printed cardboard paper with 3 ply or 5 ply corrugated sheet which is mainly used in food, beverage boxes etc.

The machine adopts chasing registration method with the help of imported low-voltage parts, liquid sensor and motion control system.

Machine Structure

Upper Feeding Part: Feed the paper of 120-450gsm. It can be thinner according to the size and quality of the paper.

Bottom Feeding Part: Feed different kinds of corrugated sheet between ABCEF 3&5 Ply.

Conveyor: Press the laminated paper and convey to the paper delivery unit.

Gluing Part: Coating glue on the bottom paper.

FAQ

1. What is your MOQ?

Our MOQ is usually 1 set.

2. Where is the delivery port?

Tianjin Port, China.

3. Can your company handle shipping for customers?

Yes. (Please provide us your requested seaport and we can check the shipping charge and arrange shipping for your order).

Hot Tags: high speed servo automatic flute laminator, China, manufacturers, suppliers, factory, price, carton, box, automatic, corrugated, high speed, Xinlian, made in China, craft punch, Thermal Heating Gluing Machine, hot melt laminating machine, Automatic Paper Feeding Gluing Machine for Gift Box, Automatic Multifunction High-Speed Flute Laminating Machine, film coating machine.

Product detail pictures:

Related Product Guide:

Our crew through skilled training. Skilled skilled knowledge, strong sense of company, to meet the company wants of customers for High definition Big Laminator - High Speed Servo Automatic Flute Laminator – Lianji, The product will supply to all over the world, such as: Kenya, Eindhoven, Nigeria, We supply professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ‘customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!

-

Best quality Automatic Rotary Slotting Machine ...

-

Excellent quality Laminator Lamination Machine ...

-

2022 wholesale price Flatbed Die Cutting Machin...

-

Chinese wholesale Die Cutting And Creasing Mach...

-

Manufacturer for Window Patching Machine - Tis...

-

Best quality Industrial Lamination Machine - H...